Industries We Serve

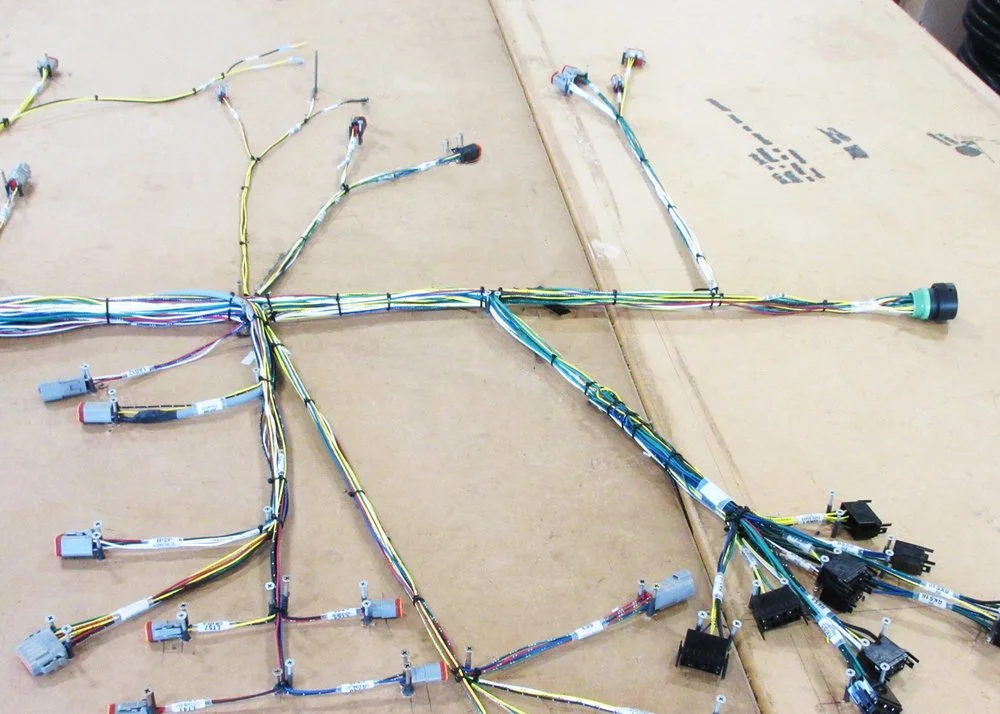

We build innovative wire harness solutions tailored to meet the needs of a wide range of industries. Our expertise in wire harness termination, braiding, ultrasonic welding, kitting, and marking guarantees that we deliver high-quality, reliable assemblies that support flawless performance and longevity in your systems. From automation and aerospace to electronics and medical devices, we serve industries that require precision, durability, and safety in their wire harnesses.

Industrial Equipment:

We build harnesses to withstand the most challenging environments. Our harnesses are built to endure vibration, heat, pressure, and moisture. ElectriPack offers precise terminations and robust braiding, with ultrasonic welding for strong, low-resistance connections. Our kitting services organize and package components for quick assembly, reducing downtime and increasing production efficiency.

Automation:

Reliability, precision, and performance are essential in the automation industry. ElectriPack delivers durable terminations, flexible braiding and loom wire coverings, and ultrasonic welding to ensure your wire assemblies perform in demanding industrial environments. From robotics to control systems and smart machinery, our solutions enhance production efficiency with accurate wire marking for streamlined assembly and maintenance, along with custom kits designed for on-site installation and quick repairs.

Agriculture:

Reliability is critical. ElectriPack’s wire harnesses offer strong, durable terminations, safe ultrasonic welds, and protective flexible braiding for long-lasting, reliable performance. Our kitting and marking solutions enhance traceability and ease of assembly, providing the correct components that your devices require to meet stringent regulatory standards while providing maximum safety and functionality.

Aerospace & Defense:

Safety and precision are non-negotiable. We build secure terminations that are verified against manufacturer specifications, custom braided harness covering, and ultrasonic welding. Our expertise allows us to provide consistent reliability in avionics, propulsion systems, and communication technologies. ElectriPack’s kitting and marking services simplify assembly. Compliance with military and aerospace regulations guarantees peace of mind for mission-critical applications.

Robotics:

ElectriPack delivers high-quality wire harnesses that provide secure connections and flexible protection for robotics, where precision and durability are paramount. Our ultrasonic welding creates strong, reliable bonds, and our kitting and marking services help streamline assembly, maintenance, and troubleshooting in robotic systems for medical, research, and industrial research applications.

Electronics:

ElectriPack delivers precise, high-performance wire harnesses to handle complex systems. Our solutions, including low-resistance ultrasonic welding and durable braiding, deliver optimal electrical conductivity and protection. Our customizable marking and kitting services streamline your processes, delivering faster and more efficient devices.

Solutions Across All Industries

ElectriPack is committed to providing quality wire harnessing solutions that meet the demands in a wide variety of industries. From low-volume custom designs to high-volume mass production, our advanced manufacturing techniques, rigorous quality control, and commitment to on-time delivery make certain that your wire harnesses are built to perform in the most demanding environments. Our ISO 9001 and WHMA certifications show our ongoing commitment to guarantee that every product meets the highest standards of quality, safety, and reliability.